CUSTOM DRYING SOLUTIONS

The ovens are running great.

I am impressed on a continuing basis with their responsiveness and stability.

Customer

DRYER DESIGNS

ASI offers many different dryer configurations and designs to meet the specific and varied needs of our customers. Our dryer designs include flotation, roll support, through-air, vertical, clean room, infrared, lab line, and inert dryers.

Flotation Dryers

ASI is a leader in flotation drying systems that use air bars to float the web through the dryer without making contact with the web. Flotation drying provides:

-

Contactless drying

-

High heat and mass transfer rates for shorter dryer or faster throughput

-

Reduced maintenance due to no moving parts in the dryer enclosure

-

Good web stability

-

Versatility in applications, web materials, and web tensions

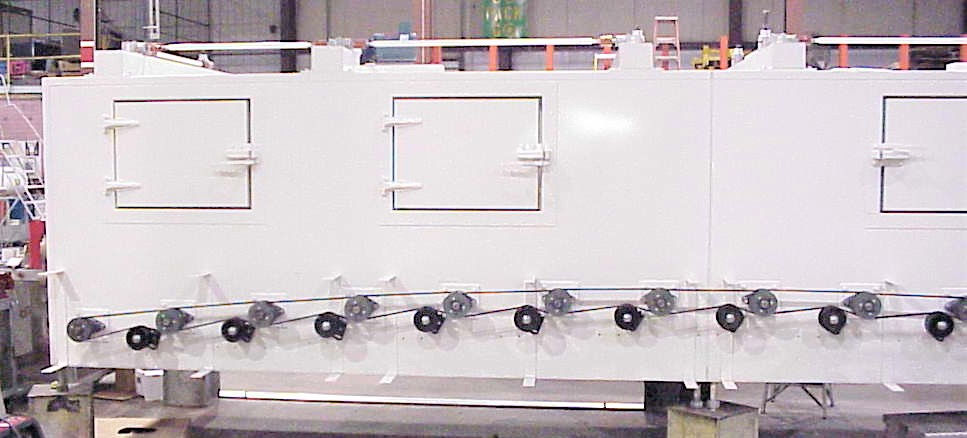

Roll Support Dryers

Roll support dryers are used for many applications and offer excellent web stability and edge curl control. Roll support drying systems can be configured in a multitude of ways, including:

-

Flat-pass or arched-roll-support

-

Direct-driven or tendency-driven idler rolls

-

Air bars above or below the web, or both, to precisely control the rate of drying

Through-Air Dryers

Through-air dryers (TADs) pull heated air through a porous web material as the web travels through the dryer on a wire or mesh belt. TADs are used for specific applications, including fiberglass mat, fiberglass veil, and other nonwovens.

For these applications, even air distribution is essential to achieving high quality, defect free product. ASI's TADs employ multiple distribution plates for controlled pressure drops and static air mixers to provide uniform air to the product.

Vertical Dryers

Vertical dryers are used when space is at a premium or to accommodate a specific web path. Common in the graphic arts industry, vertical dryers can be used for many applications and offer various configurations.

Cleanroom Dryers

Cleanroom dryers are used when the application and product require a safe and sterile processing environment, such as medical, food, electronic, and photographic products. To achieve this, a cleanroom dryer is typically constructed of stainless steel , employs HEPA filters to filter the supply and makeup air, and uses manufacturing techniques designed to reduce the possibility of contamination.

Infrared Dryers

Infrared (IR) heat uses invisible electromagnetic waves to radiantly heat the web. Infrared drying systems incorporate both air and infrared drying technologies. IR heat has many applications, including:

-

As a booster in the beginning of a dryer to heat a heavy or saturated web quickly

-

To maintain temperature throughout a cure zone

-

To reduce the energy demand of the heated air heat source

-

To shorten the overall dryer length

For converting applications, medium wave, fast response electric IR heat sources are commonly used. These IR heat sources can be panel or tube style depending on the specific application.

Lab Line Dryers

Customers routinely want a lab line drying system to test and develop new products and materials while simulating a production-line environment. Our lab line dryers allow customers to perfect their products and processes before investing in a full production line. Often, a lab line dryer must be able to perform over a wide range of operating parameters and conditions, including:

-

A wide range of operating temperatures

-

The ability to change the air bars to affect drying rates

-

Ability to simulate a production environment of varying tensions and operating conditions

Inert Dryers

Inert dryers are used when drying or curing is accomplished in an atmosphere with little to no oxygen. This allows for the drying or curing to occur in an environment with significantly higher Lower Flammability Levels (LFLs) than is allowed in normal atmospheric conditions. Inert drying requires that the web entrance and exit slots and access doors are air tight to maintain the required inert environment. Nitrogen curtains are used to seal the web slots and knife-edge seals are used to seal the doors to prevent the entry of oxygen into the drying enclosure. Oftentimes, a solvent recovery system that includes a condenser will be utilized along with an inert drying system.

PERIPHERAL COMPONENTS

In addition to custom drying solutions, ASI also provides an array of peripheral components that are often necessary to achieve a functional drying system, including:

Web Threaders

Platforms & Walkways

Structural Supports

Support Rolls

AirTurns